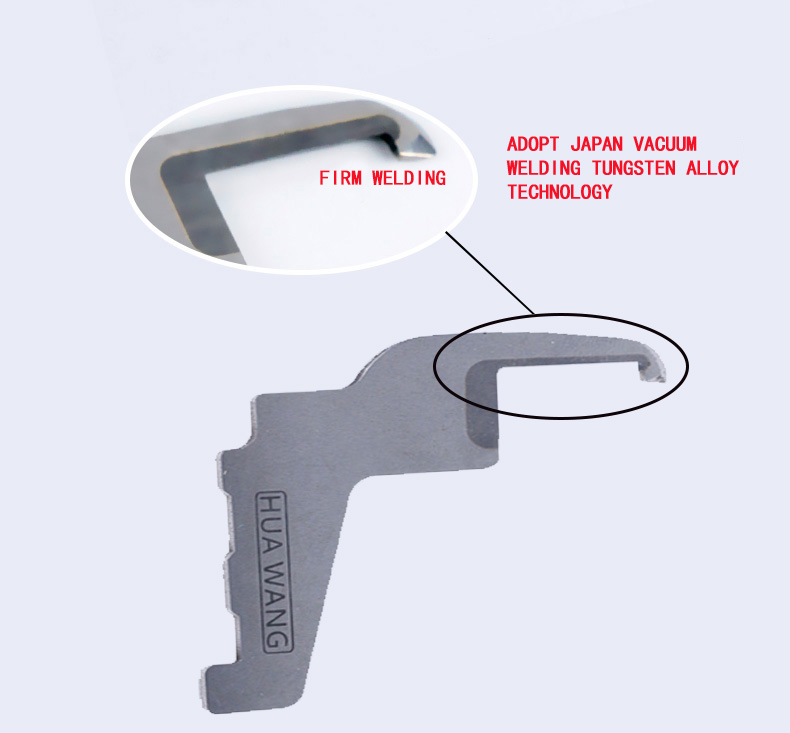

Tungsten alloy tufted carpet hook

Huawang new develops Tungsten alloy tufted hook for carpet and artificial machine. Hooks are adopting imported special steel, and the edge adopts tungsten steel(Hardness of HRA95-98), welding by the technology of vacuum welding tungsten alloy of Japan, welding high strength, firm, never shedding. Tungsten alloy steel does not break apart and the substrate (hook handle) of the hook can not be annealed, and the hardness can reach hrc61-63. Meanwhile ensures the wear of the hook sharp and the needle, which can realize stability without knocking over and dropping yarn when high-speed cutting.

Company's latest introduction of Japanese vacuum tungsten alloy welding technology, to solve the traditional welding method of tungsten alloy steel as a result of high temperature cracks, and hook body(hook handle) annealing phenomenon and big problems due to factors such as high temperature welding scrap rate, reducing the production cost. Fill the domestic industry gap. The tungsten alloy steel hook has higher strength, sharp edge and better abrasion resistance than the previous high speed steel hook. In reasonable use, the service life is 4-6 times that of ordinary hook.

The company is on the basis of continuous innovation. Import Japanese equipment and production process. From each set of procedures to be meticulous, keep improving. For the new and old customers to create more wear-resisting efficient tufting carpet machinery accessories products, and improve the hook using cycle, reducing the change rate of parts, thus enhanced the stability of the tufting carpet production and improve the productivity.

We will continue to work hard to make innovations, create more cost-effective products for new and old customers. Also for new and old friends to save more production costs, thereby creating a higher profit margins.